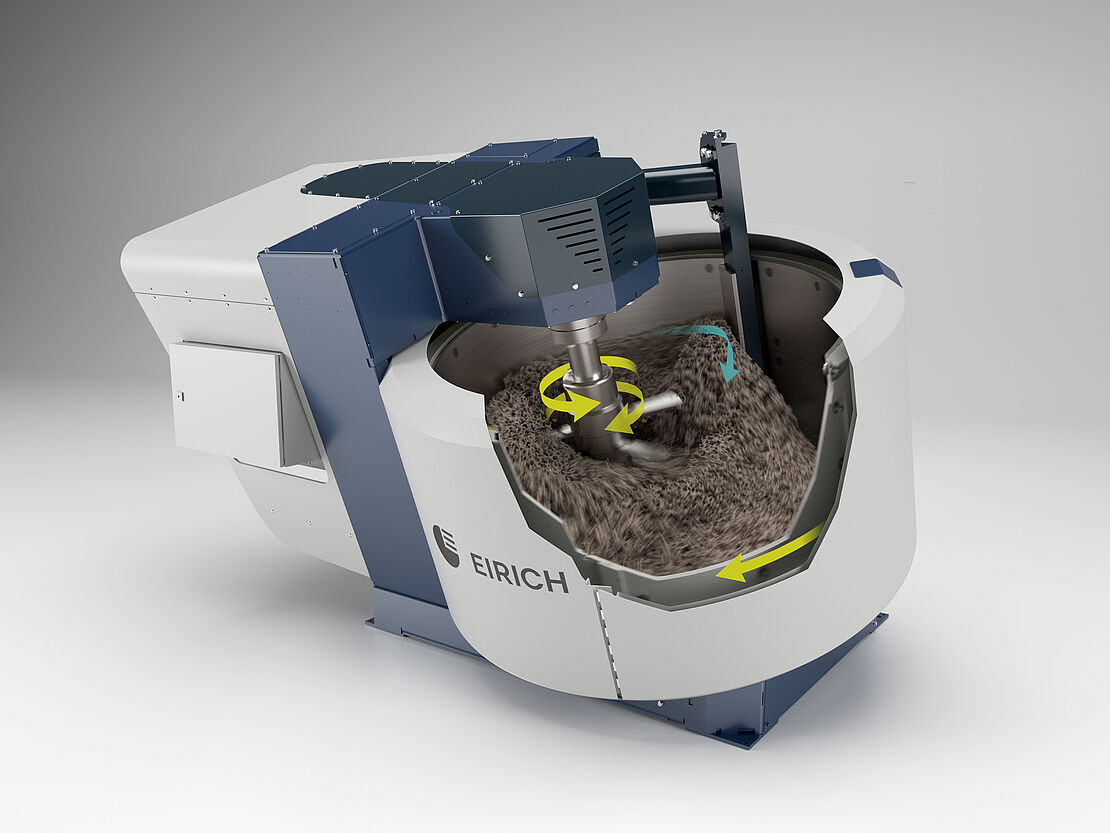

Our production mixers set standards in quality, efficiency and process reliability. Whether in the construction materials industry, chemicals, ceramics, metallurgy or battery production, Eirich supplies reliable solutions for batches up to 12,000 liters and throughput rates of up to 1,500 t/h. Robust. Scalable. Tried and tested worldwide.

Eirich for all

Expandable modular system allows tailored solutions

Thanks to the modular system, our machines can be adapted to suit precise customer requirements without having to do without proven core technology. This ensures tailored solutions on a common foundation: Quality, efficiency, and reliability – made by Eirich.

Machine variants

Standard(R & D-type)

Eirich mixers in tilted form

For mixing, granulating, plasticizing or kneading and coating.

Hinged (W-type)

Eirich mixers with hinged pan cover

For simple and efficient cleaning of the mixing chamber and tools.

Dissolving mixer (L-type)

Eirich MixSolver® with horizontally mounted mixing pan

For the manufacture of products in liquid, paste-like and viscous form or with a high solids content.

Applications

Concrete, refractory materials, ceramics, foundry products, fertilizers, and many more

Applications

Li-ion batteries,fertilizers, welding powder, graphite compounds, specialist concrete, and many more

Applications

Dispersants, ceramic slips, slurries (e.g. Li-ion batteries), sealing compounds, ready-to-use plaster, and many more

Variety of equipment options for multipurpose processors

All features at a glance

- Continuous or batchwise operation

- Processing under vacuum

- Flexible energy input

- W-type

- Effective volume from 250 to 12,000 liters

- Heater

- Cooling

- Double-jacket temperature regulation

- ATEX

- Optimized wear protection

- Individual inclination

The unique Eirich intensive mixer – perfectly tailored to your specific process. Wear protection, tools, drives and machine geometry adapted and optimized to the particular process task. From dry to liquid, from soft to highly abrasive.

For more information, download our product brochure:

(pdf, 1 MB)

Eirich Intensive Mixer

The perfect accessory for every requirement

Check out the extensive range of accessories for your Eirich mixers. From special mixing tools through smart cameras to powerful cleaning systems – at Eirich, you will find everything you need for optimizing the operation of your machine.

Our accessories not only optimize the efficiency and flexibility of your mixing processes, but also help to extend the life and improve the reliability of your systems. Improve your production processes with Eirich accessories.